From Blueprint to Reality The Art and Science of CNC Machining

In the world of manufacturing, Computer Numerical Control (CNC) machining stands as a testament to the fusion of art and science. This sophisticated technology has transformed the way products are designed, developed, and produced, revolutionizing industries from aerospace to consumer goods.

Precision at Its Finest

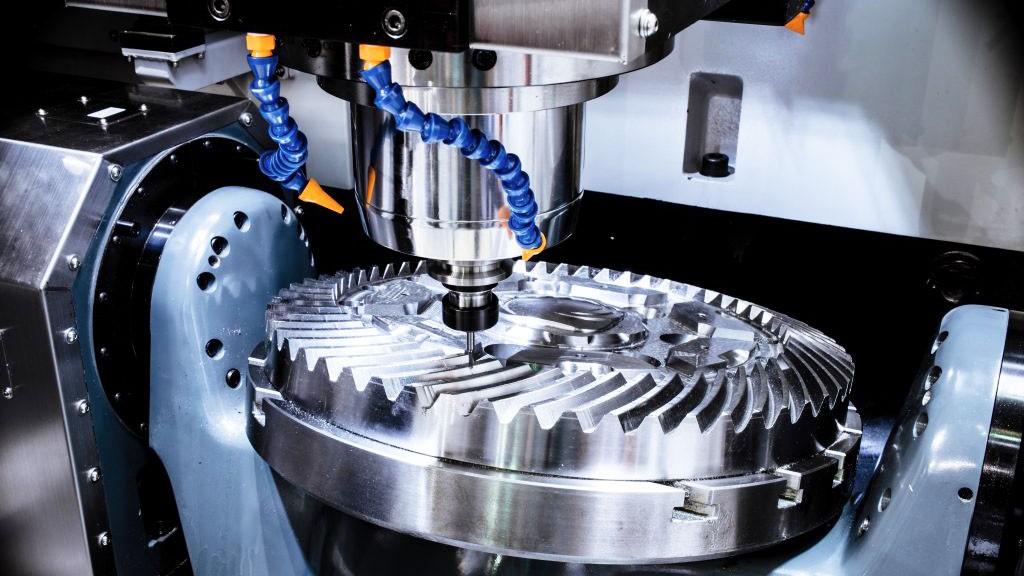

CNC machining utilizes computerized controls to direct machine tools in the shaping of material into precise forms. The process begins with a digital blueprint, created using computer-aided design (CAD) software. This blueprint serves as the roadmap for the CNC machine, guiding it to cut, mill, drill, or engrave materials with exacting precision.

One of the key advantages of CNC machining is its ability to produce highly accurate components consistently. Unlike manual machining, which relies heavily on the skill and experience of the operator, CNC machines follow programmed instructions to perform tasks with remarkable uniformity. This precision is crucial in industries where even the smallest deviation can lead to significant issues. For instance, in aerospace manufacturing, the precision of CNC machining ensures that every component fits perfectly, contributing to the safety and performance of aircraft.

The Art of Customization

While CNC machining is rooted in precise engineering, it also offers a significant degree of customization. Designers and engineers can experiment with complex geometries and intricate designs that would be challenging or impossible to achieve with traditional methods. This capability has expanded the creative possibilities for product designers, enabling the production of bespoke items tailored to specific requirements.

The ability to rapidly prototype and iterate designs is another benefit of CNC Machining. By quickly producing prototypes, manufacturers can test and refine their designs before committing to full-scale production. This iterative process accelerates innovation and allows for faster time-to-market for new products.

The Science behind the Machines

CNC machines operate on advanced principles of engineering and computer science. The machines are equipped with high-speed processors and sophisticated software that control every aspect of the machining process. Sensors and feedback systems ensure that the machine maintains the correct parameters throughout the operation, adjusting for any deviations in real-time.

Materials used in CNC machining range from metals and plastics to composites and wood. Each material has its own properties and challenges, and CNC machines are designed to handle a variety of them with precision. The choice of material and machining parameters can significantly impact the final product’s quality and performance.

Looking Ahead: The Future of CNC Machining

As technology continues to evolve, CNC machining is expected to see even more advancements. Innovations such as machine learning, artificial intelligence, and improved materials science are likely to further enhance the capabilities and efficiency of CNC machines. These developments promise to push the boundaries of what is possible in manufacturing, continuing to blend the art and science of CNC machining in new and exciting ways.

In summary, CNC machining represents a harmonious integration of artistic creativity and scientific precision. Its ability to transform digital blueprints into tangible, high-quality products has made it an indispensable tool in modern manufacturing, driving innovation and ensuring excellence across various industries.