Layered Perfection the Science and Strategy Behind 2 Shot Injection Molding

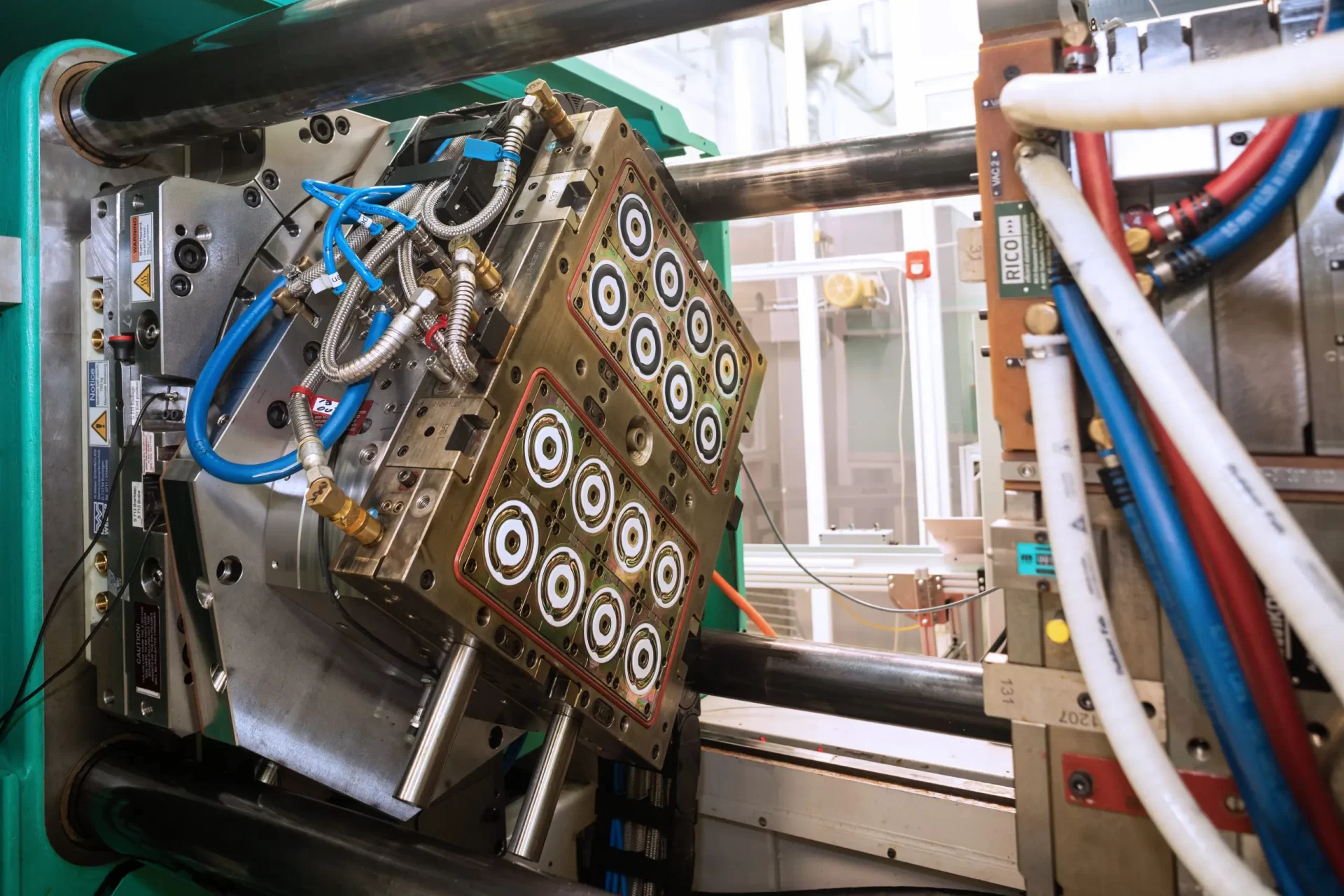

Imagine a world where products are not just functional but also aesthetically pleasing and ergonomically designed. Enter the realm of 2 Shot Injection Molding, a revolutionary manufacturing technique that marries efficiency with creativity. This innovative process allows for the simultaneous molding of two different materials into one seamless product, resulting in stunning designs and enhanced functionality. Whether you’re developing consumer goods or intricate industrial components, understanding the science and strategy behind this method can elevate your projects to new heights. Let’s dive into the strategic considerations, design elements, and real-life success stories that showcase why 2 Shot Injection Molding is a game changer in modern manufacturing.

Strategic Considerations for Successful Implementation

When implementing 2 Shot Injection Molding, strategy is crucial. First, assess your materials carefully. Different polymers can alter the final product’s performance and aesthetics.

Next, consider your production volume. This method shines with high-volume runs where efficiency becomes paramount. It’s essential to balance upfront investment against long-term savings.

Collaboration plays a key role too. Engage engineers early in the design phase to ensure compatibility between materials and molds. Their insights can prevent costly mistakes down the line.

Don’t overlook tooling costs either; they can be significant but are often offset by reduced cycle times and waste during manufacturing.

Remain adaptable throughout the process. Market demands change rapidly, so being open to adjustments will keep you ahead of competitors utilizing traditional methods.

Design Considerations for Two-Shot Injection Molding

When designing for two-shot injection molding, the first step is understanding material compatibility. It’s essential to choose materials that bond well and create a seamless finish. Incompatible materials can lead to weak spots or delamination.

Next, consider the geometry of your design. Complex shapes may require special tooling and precise alignment during manufacturing. Streamlined designs often reduce production costs while maintaining functionality.

Draft angles are another critical aspect. They facilitate easy part ejection from molds without causing damage. A well-thought-out draft angle enhances efficiency in the process.

Anticipate potential issues such as sink marks or warping due to thermal cycles between shots. Addressing these factors early on can save time and resources later in development, ensuring a smoother path from concept to completion.

Real-Life Examples of Successful 2 Shot Injection Molding Projects

The world of 2 Shot Injection Molding is full of innovation and creativity. Companies across various industries have embraced this technique to enhance their products and streamline production processes.

One standout example comes from the automotive sector. A leading manufacturer developed a two-component dashboard using this method. The first shot created a rigid base structure, while the second applied a soft-touch layer for improved comfort. This not only elevated user experience but also reduced assembly time by combining multiple components into one streamlined part.

In consumer electronics, another notable project involved smartphone cases designed with both hard plastic and rubberized materials. The hard shell provided protection, while the rubber offered grip. By utilizing 2 Shot Injection Molding, manufacturers could produce these complex designs efficiently without secondary bonding processes.